Corrosion Resistant Clamps

Corrosion Resistant Clamps

Corrosion/abrasion is an important problem that causes deterioration in pipe assemblies. Corrosion of pipes over time reduces the efficiency of the assembly and increases maintenance and repair costs.

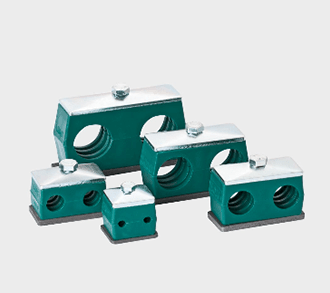

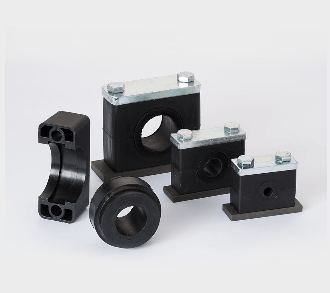

Corrosion Resistant Clamps produced by LMC Makina are specially designed fixing solutions to prevent rusting and corrosion for use in pipe assemblies adversely affected by water, moisture, chemicals and weather conditions. Manufactured from corrosion resistant raw materials or coated with special materials, these clamps contribute to the long life of the pipes. LMC Makina's Corrosion Resistant Clamps, which are used in a wide range of areas from industrial assemblies that need to operate under harsh conditions such as maritime, chemical, oil and natural gas to outdoor applications, support the safe fixing of pipes as well as protecting them from corrosion. Corrosion Resistant Clamps are also widely used in HVAC assemblies, water and waste water pipelines in buildings.

Corrosion Resistant Clamps are produced with special raw material contents researched and developed in laboratory environment. Metal parts are generally stainless steel.

Stainless steel stands out with its high corrosion resistance and durability and can be used for a long time without rusting even in harsh environmental conditions. For these reasons, Corrosion Resistant Clamps produced by LMC Makina are preferred in pipe assemblies adversely affected by water, salty air or chemicals.

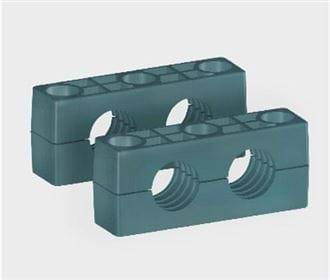

In addition to the raw materials, the design of the clamps is also aimed at preventing corrosion.

It is important that the type of clamp used in the installation process of pipe assemblies can be applied quickly and easily. Corrosion Resistant Clamps are suitable for the pipe diameters to be used and the pressure level of the assembly are also important selection criteria.